Contents

Previous

Next

STL, which stands for Standard Triangulation Language or Standard

Tesselation Language is a file format used by stereolithography

software. STL-Files describe the surface of 3-dimensional objects.

BURRTOOLS can export single shapes into STL files so that 3D printers

can quickly fabricate prototypes of them.

Introduction to 3-D printing

There are two popular forms of 3-D printing: SLS and FDM.

The SLS (ShapeWays and TNO) laser sinters nylon. ShapeWays currently

charges by the volume of sintered nylon. SLS pieces are always white.

FDM (Stratasys) charges by the time it takes to make the piece. It

has two modes: solid and sparse. Sparse mode is quicker and uses less

material. In sparse mode the interior of the pieces are honeycombed.

Having a hollowed piece will be cheaper and quicker for SLS — it

will be the same cost and speed for FDM because a hollow piece will

still have a support structure inside the hollow, but it will be of a

different material. The thing to realize is that with SLS, if there are

no holes to the hollow part of the piece, the nylon "sand" will be

captured. This should not be a problem except for the weight of the

piece. But keep in mind that some printing services will charge you for

the surrounded volume as well as the for the actually printed volume.

Exporting

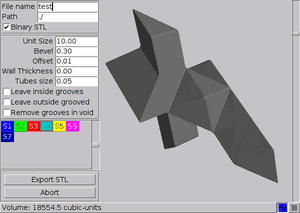

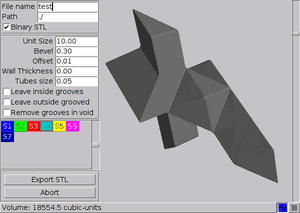

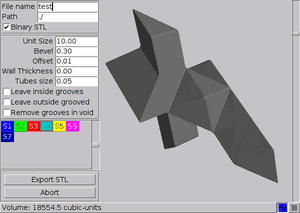

The main menu entry Export - STL opens the window seen

in Figure StlExportWindow. The window

has a shape selector, a 3-D view of the selected shape and some

parameters that control the shapes created. The exact parameters depend

on the grid of the current puzzle. The 3-D view displays the shape the

same way as it will be exported into the STL file, so you can see what

the shape will look like.

On the bottom in the status line you can see what volume the current

shape with the current settings has.

In the status line are also two buttons to choose how the shape is

displayed. Either normally from the outside. The 2nd view will show you

the inside of the shape. This is useful if you print hollow shapes and

need to see what the internal void looks like.

Figure: The STL-Export window

Hollow Shapes

There are mainly 2 different exporters. One for the sphere puzzles

and one for all other polygon based puzzles.

When creating spheres you can simply create hollow shapes by giving

the inner radius a value that is different from zero. The resulting

shapes will automatically have a lot of holes that connect the inside

and the outside. Those holes will be symmetrically placed and they are

in places on the sphere where they normally don't interfere with

solving.

For polygon based puzzles things are not that simple. Here a hole at

the wrong place could make pieces stop from sliding or get stuck into

one another. That is why you can specify where exactly you want the

holes. Initially there are no holes at all. By shift-clicking onto

faces of voxels you can "drill" a hole through this face. The hole will

always be in the centre of the face. Ctrl-clicking on the face will

remove the hole again.

Don't forget to first set a proper wall thickness and tube size to

actually see the holes.

Parameters

The following parameters control the generated shape and file.

Filename and Path control the name and

path of the generated file. Those are common parameters for all grids.

Binary STL: controls whether a binary or a text STL

file is created. Normally binary files are the right choice because

they are much more compact. But sometimes it might be useful to use the

text form. For example when you want to see what is going on in the

inside of an STL file, or when your printing service has problems with

the binary file.

For polyhedron based grids there are the following parameters that

control the shape of the generated pieces

- Unit Size: controls the base length of the created

voxels.

- Bevel: controls the size of the bevel

- Offset: allows a gap between the pieces, so that it is

actually possible to assemble them. If the shapes were made to correct

sizes they would touch, making movement impossible.

- Wall Thickness: controls how thick the wall of

material will be that encloses the internal void. When the wall

thickness is zero, then the piece will be solid. The piece will be

solid as well, when you make the wall too thick.

- Tube size: is the size of the "tubes" that connect the

inside void with the outside world. The size is given relative to the

size of the shape where the tube is located. So 0 means no holes and 1

means tubes as big as the face that the tube is on. The "tube" is

actually a hole of the same shape as the face that it is on. So if you

put it onto a square face of a voxel you will get a square hole.

- Leave inside grooves: will, when tagged leave a lot of

grooves in the generated shape so that the shape looks like it is glued

out of a lot of singe voxels.

- Leave outside groved: will only leave the grooves on

the outside of the shape but will fill all the grooves that will

actually go through the generated shape. To understand the difference

of these 2 options, build a shape out of 2x2x2 cubes and look at the

different shapes. Use a bigger bevel and offset to better see the

differences.

- Remove grooves in void: controls whether the grooves

will be removed from the shape of the inner void. Less grooves will

result in less material but more grooves might be a more stable result.

So you may need to experiment what the effects of this option are on

the printed result.

For spheres the parameters are as follows:

- Sphere radius: controls the gap between the centres of

the single spheres. It also is the maximum radius the spheres can have.

This value is in output units

- Connection radius: controls the radius of the

connection cylinder between the spheres. As the spheres mathematically

only touch in one point connectors need to be added. Those connectors

are cylinders. The radius of those cylinders can maximally be so that

they touch one another. If this value is 1 then the cylinders have

their maximal radius, 0 would mean no connection.

- Curvature radius: controls the radius of the

transition between sphere surface and cylinder surface. If this value

is 0 no transition is done and there will be a bend in the surface. If

the value is 1 the maximally possible area will be used to go from

sphere surface to cylinder surface. When there is only little or no

space for the transition (e.g. when the connection radius is close to

1) there might be a bend, even when this value is close to 1.

- Offset: just like with the other grids this makes the

spheres smaller to make the puzzle actually assembable. This is in

output units. Keep the values small if you want to have working

puzzles. Most puzzles might not even require a value larger than zero.

But you can get cool mathematical objects with a bigger offset

- Recursions: controls the number of used triangles to

approximate the surfaces. A value one bigger will result in

approximately 4 times as many triangles and accordingly smoother

surface but also bigger STL files. Don't make it too big as it will

result in long calculation times and huge files! Normally a value of 3

or 4 is enough.

- Inner radius: controls the radius of the hole inside

the sphere. This radius must be smaller than the sphere radius from

above. The difference of these 2 values defines the wall thickness of

the sphere. The Offset is applied to both values in the same way so

that the wall thickness stays constant.

- Hole diameter: controls the diameter of the hole that

connects the void inside the sphere with the outside world. If you

leave that value 0 the inside of the sphere will be completely

surrounded by the sphere itself and material inside the sphere can not

get out. Depending on the printing process that might not be a wise

choice.

- Square Hole: the hole from above can be round or

square. This is mainly a matter of taste, so make your choice.

Contents

Previous

Next